2 min read

The Bradbury BOSS Shear Brings Speed and Accuracy to Rollforming Lines

BRADBURY B.O.S.S.™ HIGH SPEED, CLOSE TOLERANCE FLYING SHEAR There are approximately 300 Bradbury Orbital Servo Shears (B.O.S.S.™) installed around...

2 min read

BRADBURY B.O.S.S.™ HIGH SPEED, CLOSE TOLERANCE FLYING SHEAR There are approximately 300 Bradbury Orbital Servo Shears (B.O.S.S.™) installed around...

1 min read

The Bradbury Group offers a line of roll forming machines that can help take some of the challenges out of manufacturing deep profiled metal building...

1 min read

The Bradbury Group will be exhibiting at Frame Building Expo 2016 in Indianapolis, Indiana, March 9th through 11th. Stop by and visit with us at...

1 min read

The Bradbury Co., Inc. has a new video featuring a Multi Profile Trim Roll Former. This machine produces the following four profiles: R-Panel Jamb...

In addition to updates to our stocking equipment list, the following used items have been added: Bradbury Zee Purlin Line with front end equipment...

The Bradbury Co., Inc. received a new testimonial from Tri County Metal Sales, LLC. Darrell Meador stated, "Quality and service are excellent. It's...

1 min read

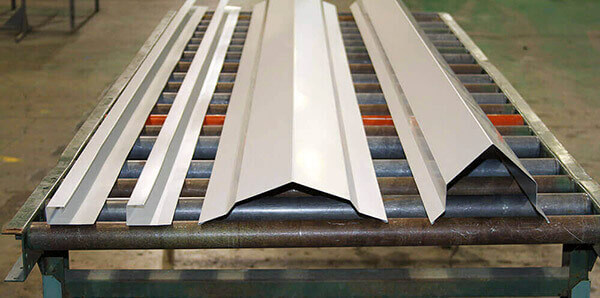

The Bradbury Co., Inc. develops a W Valley roll former to accompany an extensive line of equipment to manufacture metal trim profiles. Typically roof...

Receive notifications when we update the used equipment list!