1 min read

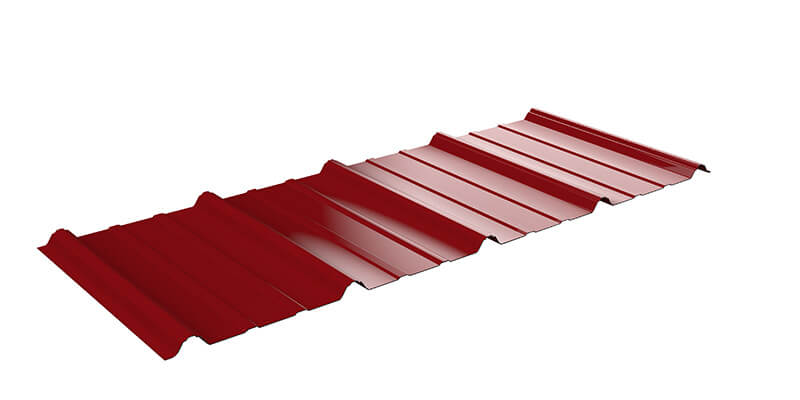

Pre-Owned Canopy Panel Rollformer Available Now

At The Bradbury Group we currently have a used canopy panel roll former, ready for immediate delivery. This machine is located at our headquarters in...

1 min read

At The Bradbury Group we currently have a used canopy panel roll former, ready for immediate delivery. This machine is located at our headquarters in...

1 min read

We are excited to announce that Ben Schmidt, Industry Sales Manager at The Bradbury Co., Inc., will be presenting at the 2025 Garage, Shed, Carport...

2 min read

At The Bradbury Group, we are always looking for ways to enhance our roll forming lines. Our latest innovation is an advanced method for...

.png?width=1500&height=750&name=Hayes%20Flying%20Post%20Cut%20(1).png)

2 min read

Hayes International, located in Rotorua, New Zealand and part of The Bradbury Group, offers high-quality Panel roll formers that can be equipped with...

3 min read

With its wide range of advantages, Bradbury's AG roll tooling stands above its global competitors. Renowned for its ability to produce top-notch...

1 min read

Bradbury announces a new partnership with Biegemaster, serving as the North American distributor for the XBend folder. This collaboration allows...

2 min read

Are you struggling to increase your rollforming throughput? Chances are that inefficiencies in various processes like loading coils, packaging,...

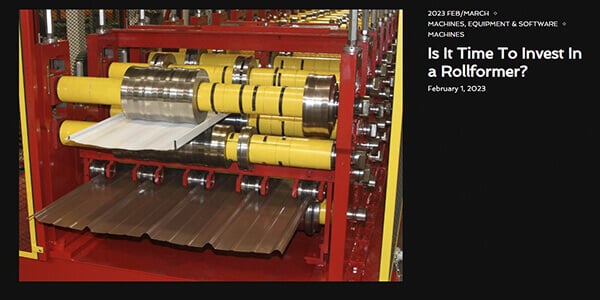

Are you considering purchasing your first roll former to produce metal building panels? Would you like some advice from a trusted expert? Ben...

2 min read

BRADBURY B.O.S.S.™ HIGH SPEED, CLOSE TOLERANCE FLYING SHEAR There are approximately 300 Bradbury Orbital Servo Shears (B.O.S.S.™) installed around...

1 min read

Do you want to produce tight tolerance metal building trim parts at a faster rate? The Bradbury 5X trim roll former offers several advantages for...

Receive notifications when we update the used equipment list!