1 min read

FAQ: How is End Flare controlled in Roll Formed Profiles?

End flare can be inherent in roll formed parts, especially when produced on a precut roll forming line as opposed to a post cut line which forms the...

2 min read

Rachel Grilliot May 25, 2023 2:30:01 PM

Are you struggling to increase your rollforming throughput? Chances are that inefficiencies in various processes like loading coils, packaging, entering orders, and maintenance upkeep limit your production. These inefficiencies result in significant downtime, leading to monetary losses. Have you considered conducting a time study to determine how long your rollforming line sits idle throughout the day? What is causing this idle time? It could be a machine that takes extra time to set up for an acceptable profile or the time it takes to load and thread the line with the coil, or even the time spent packaging the product. There are various options to consider that will increase the productivity of your rollforming line.

Are you struggling to increase your rollforming throughput? Chances are that inefficiencies in various processes like loading coils, packaging, entering orders, and maintenance upkeep limit your production. These inefficiencies result in significant downtime, leading to monetary losses. Have you considered conducting a time study to determine how long your rollforming line sits idle throughout the day? What is causing this idle time? It could be a machine that takes extra time to set up for an acceptable profile or the time it takes to load and thread the line with the coil, or even the time spent packaging the product. There are various options to consider that will increase the productivity of your rollforming line.

One way to boost production is to replace certain components in your existing line. For instance, replacing your single mandrel uncoiler with a double end can bring coil changes down to a few minutes. Likewise, switching your stationary shear to a Bradbury B.O.S.S.™ flying shear, which has production speeds up to 300 fpm, will increase your panel line production. You can also consider investing in an inline shrink wrapper for finished packs or a stacking system that can discharge the stack of panels out of the way faster, allowing your rollforming line to continue to run. However, purchasing new equipment is not always feasible, considering longer lead times on manufacturing equipment and budget constraints.

few minutes. Likewise, switching your stationary shear to a Bradbury B.O.S.S.™ flying shear, which has production speeds up to 300 fpm, will increase your panel line production. You can also consider investing in an inline shrink wrapper for finished packs or a stacking system that can discharge the stack of panels out of the way faster, allowing your rollforming line to continue to run. However, purchasing new equipment is not always feasible, considering longer lead times on manufacturing equipment and budget constraints.

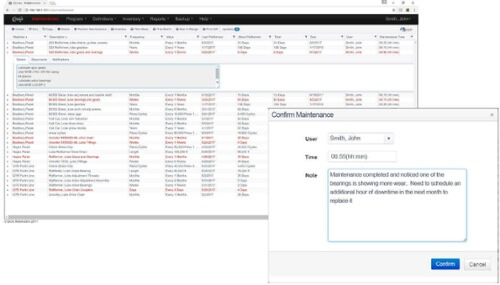

There are production-increasing options that tend to get overlooked but only take a few weeks or even days to accomplish. Upgrading your controls is one such option. If your operators spend extra time entering production orders at the line, it may be time to upgrade your control system. Beck Automation's multi-batch controls can display multiple orders  and allow the operator to make changes at the roll forming line. With a networkable control system, orders can be downloaded from the office ERP or design software directly to the machine, saving production time and minimizing the chance of errors. You can also send additional data when downloading information to the line, allowing an integrated printer to produce packing lists and bundle tags at the production line for completed orders.

and allow the operator to make changes at the roll forming line. With a networkable control system, orders can be downloaded from the office ERP or design software directly to the machine, saving production time and minimizing the chance of errors. You can also send additional data when downloading information to the line, allowing an integrated printer to produce packing lists and bundle tags at the production line for completed orders.

Maintenance issues or breakdowns can also lead to significant production downtime. Due to the labor shortage, many companies feel compelled to minimize or eliminate maintenance departments, leaving the operators responsible for machine maintenance. The cost of downtime and emergency technician trips can be expensive. Bradbury maintenance programs can be a great way to perform preventative maintenance and keep your rollforming line running in top condition. These maintenance contracts cost less than paying technicians to travel on demand because they can be scheduled in advance and at regular intervals. While at your facility, the technician can train new operators, refresh the knowledge of your existing staff, and review your spare parts inventory to recommend any new parts that may be a problem due to supply chain delays.

Maintenance issues or breakdowns can also lead to significant production downtime. Due to the labor shortage, many companies feel compelled to minimize or eliminate maintenance departments, leaving the operators responsible for machine maintenance. The cost of downtime and emergency technician trips can be expensive. Bradbury maintenance programs can be a great way to perform preventative maintenance and keep your rollforming line running in top condition. These maintenance contracts cost less than paying technicians to travel on demand because they can be scheduled in advance and at regular intervals. While at your facility, the technician can train new operators, refresh the knowledge of your existing staff, and review your spare parts inventory to recommend any new parts that may be a problem due to supply chain delays.

Increasing production from your existing line does not necessarily mean purchasing newer, faster equipment. It may involve implementing a new streamlined process or rethinking how you maintain your equipment. Reach out to The Bradbury Group rollforming experts to discover how we can help increase your production.

+1.620.345.6394

1 min read

End flare can be inherent in roll formed parts, especially when produced on a precut roll forming line as opposed to a post cut line which forms the...

1 min read

Metal Building panels with felt underlayment applied can look just as good as panels manufactured without. However, it does take some changes in the...

1 min read

Beck Automation is a leading control system provider for the metal forming industry. Their products make production machines more efficient and...