1 min read

Automating the Future: Beck Automation Custom Robotic Folder Solution

Manufacturing facilities continue to look for ways to streamline production, improve efficiency, and make the most of their workforce. Beck...

.jpg?width=1800&height=900&name=Beck%20Automation%20(1).jpg)

1 min read

Manufacturing facilities continue to look for ways to streamline production, improve efficiency, and make the most of their workforce. Beck...

.png?width=500&height=250&name=Norwalk%20UnCoiler%20PRE%20Header%20(1).png)

2 min read

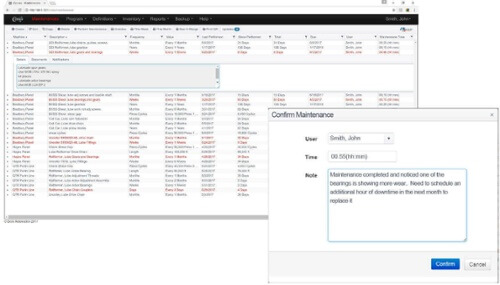

In the fast-paced world of manufacturing, efficiency and seamless operation are paramount. Norwalk Innovation, a leader in industrial equipment,...

2 min read

BRADBURY B.O.S.S.™ HIGH SPEED, CLOSE TOLERANCE FLYING SHEAR There are approximately 300 Bradbury Orbital Servo Shears (B.O.S.S.™) installed around...

3 min read

Bradbury Provides Roll Forming Solution for MicroMetl Moundridge, Kan., May, 2021 — MicroMetl is the nation’s largest independent manufacturer of...

2 min read

End flare can be inherent in roll formed parts, especially when produced on a precut roll forming line as opposed to a post cut line which forms the...

1 min read

Beck Automation is a leading control system provider for the metal forming industry. Their products make production machines more efficient and...

The Bradbury Light Structural Steel Framing line is designed to produce 14 ga. - 20 ga. stud and track products at speeds up to 500 FPM. The typical...

1 min read

Bradbury's bridge deck roll forming line is able to produce a closed end bridge deck profile. This line includes a 20,000 lb capacity uncoiler,...

1 min read

The Bradbury Co., Inc. has a new video featuring a Flying Patriot Shear. This machine can be retrofitted into an existing line or purchased with a...

1 min read

Hayes recently installed a corrugated curver for the US market at Bridger Steel in Montana. The fully automated machine will allow Bridger Steel to...

Receive notifications when we update the used equipment list!