1 min read

Automating the Future: Beck Automation Custom Robotic Folder Solution

Manufacturing facilities continue to look for ways to streamline production, improve efficiency, and make the most of their workforce. Beck...

.jpg?width=1800&height=900&name=Beck%20Automation%20(1).jpg)

1 min read

Manufacturing facilities continue to look for ways to streamline production, improve efficiency, and make the most of their workforce. Beck...

1 min read

Once again, three Bradbury Group representatives are speaking at the FMA World-Class Roll Forming Workshop. The Fabricators & Manufacturers...

1 min read

Two Bradbury Group experts will lead classes at the 2022 World-Class Roll Forming Workshop. The workshop will take place April 11 - 13 in Memphis,...

1 min read

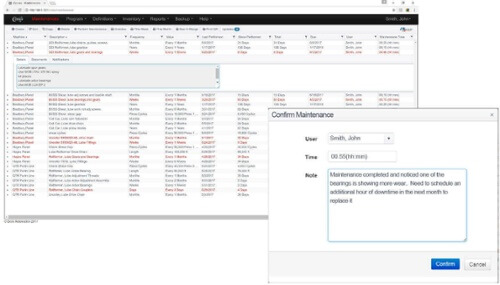

Evaluate your needs. Know your options. Utilize available technology. The phrase "inventory management" has various meanings to manufacturing...

1 min read

Beck Automation is a leading control system provider for the metal forming industry. Their products make production machines more efficient and...

The Bradbury Co., Inc. received a new testimonial from Richards-Wilcox. Alan Adams stated, "We are extremely happy with our decision to partner with...

1 min read

Brock Miesner, Controls Technician for Beck Automation, LLC, received a silver medal at the 43rd WorldSkills Competition in Sao Paulo, Brazil....

Receive notifications when we update the used equipment list!