Rachel Grilliot

2 min read

Bradbury Group Acquires Press Room Equipment Co.

The Bradbury Group, the global leader in the design and manufacture of roll forming and coil processing equipment, announced today that it has...

1 min read

Bradbury Group Hires Antonio Gallo as European Sales Leader

The Bradbury Group, a leading roll forming and coil processing equipment manufacturer, has appointed Antonio Gallo as its new European Sales Leader....

1 min read

Bradbury expands Double-Bend folder offering with Biegemaster XBEND

Bradbury announces a new partnership with Biegemaster, serving as the North American distributor for the XBend folder. This collaboration allows...

2 min read

FAQ: How can I increase production on my existing rollforming line?

Are you struggling to increase your rollforming throughput? Chances are that inefficiencies in various processes like loading coils, packaging,...

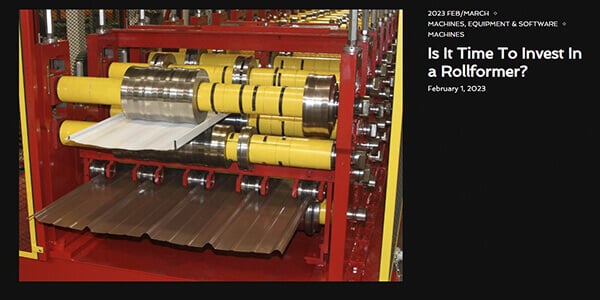

Is it time for you to invest in a Panel rollformer?

Are you considering purchasing your first roll former to produce metal building panels? Would you like some advice from a trusted expert? Ben...

1 min read

Bradbury Group Professionals to Speak at FMA Roll Forming Workshop

Once again, three Bradbury Group representatives are speaking at the FMA World-Class Roll Forming Workshop. The Fabricators & Manufacturers...

_tny.png?width=600&height=300&name=CR%20Slitters%20image_featured%20image%20(2)_tny.png)

1 min read

CR Slitters Purchases Athader High Production Slitting Line

CR Slitters and Athader S.L. (The Bradbury Group) are pleased to announce CR Slitters purchase of a High Production Slitting Line from Athader. The...

%20sm.jpg?width=800&height=400&name=Image%20for%20blog%20(2)%20sm.jpg)

1 min read

Modern Metals Article features Athader slitting line at Bailey Metal

Modern Metals published an article in their August 2022 issue highlighting Bailey Metal Products' decision to purchase an Athader slitting line and...

1 min read

Bradbury Professionals to share Industry Expertise at Metalcon 2022

Join The Bradbury Group in booth #1207 at Metalcon 2022, the only global event dedicated exclusively to metal application in design and construction....

Sign up to receive the latest news from The Bradbury Group

Receive notifications when we update the used equipment list!