4 min read

Celebrating 65 Years of Excellence: Bradbury Company Marks a Milestone

We are excited to announce that the Bradbury Co., Inc. is proudly celebrating its 65th anniversary this year. As we reflect on our journey, it's...

.png?width=1162&height=600&name=2023%20Group%20Locations%20map_No%20logos%20underneath-011%20(1).png)

4 min read

We are excited to announce that the Bradbury Co., Inc. is proudly celebrating its 65th anniversary this year. As we reflect on our journey, it's...

2 min read

Roll forming lines can be configured in two ways to create length-specific formed parts. One method is pre-cutting, which involves cutting the steel...

2 min read

Are you struggling to increase your rollforming throughput? Chances are that inefficiencies in various processes like loading coils, packaging,...

2 min read

End flare can be inherent in roll formed parts, especially when produced on a precut roll forming line as opposed to a post cut line which forms the...

2 min read

Calendering: A process that plays a part in all our lives, yet most of us have no idea what it is. From disposable diapers to dryer sheets, to...

1 min read

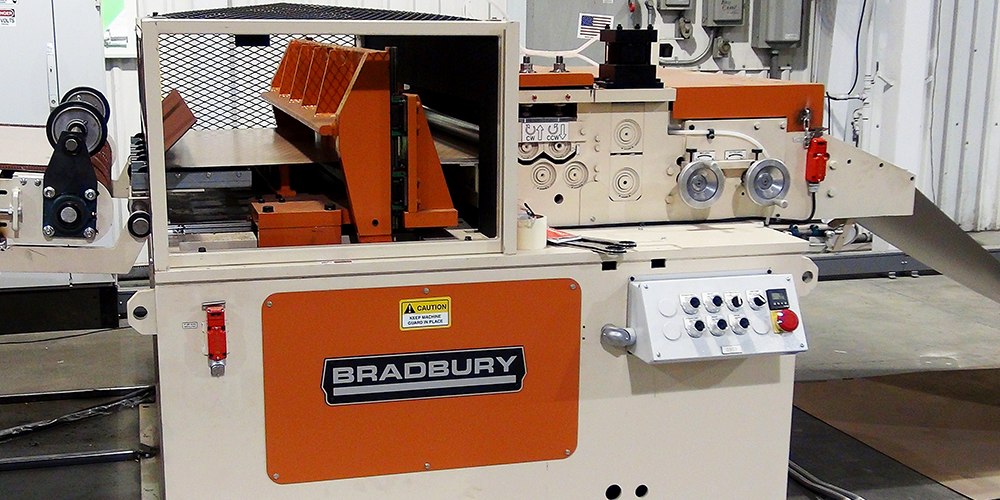

Bradbury's largest leveler series to date includes a heavy gauge eDrive® leveler (U.S. Patent #8893537) and production shear, capable of processing...

1 min read

Metal Building panels with felt underlayment applied can look just as good as panels manufactured without. However, it does take some changes in the...

1 min read

Moundridge, KS – The Bradbury Co., Inc., serving as the world headquarters for the global group of companies known as The Bradbury Group, hosted a...

Receive notifications when we update the used equipment list!