1 min read

FAQ: How is End Flare controlled in Roll Formed Profiles?

End flare can be inherent in roll formed parts, especially when produced on a precut roll forming line as opposed to a post cut line which forms the...

1 min read

Matt Werner Apr 16, 2019 10:33:18 AM

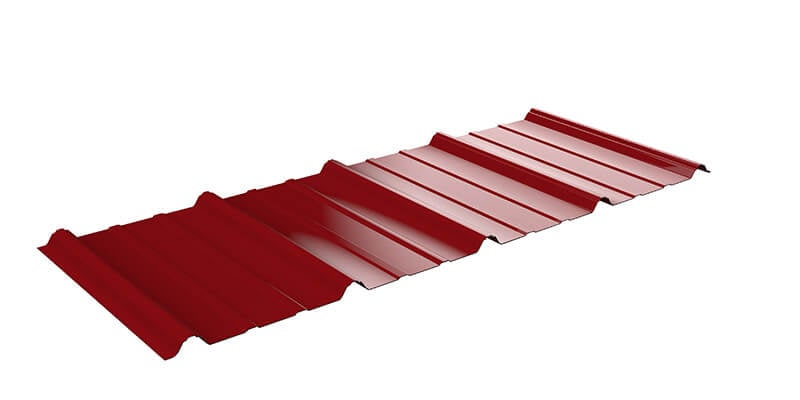

Metal Building panels with felt underlayment applied can look just as good as panels manufactured without. However, it does take some changes in the roll tooling design.

The demand for felt applied metal roof and wall panels is growing, typically used for controlling condensation build up or sometimes used for sound deadening applications. Many manufacturers have tried to apply the felt on their existing panel roll forming lines and have found it can be difficult to produce a panel without major cupping. Usually the overlap and underlap sides of the panel curl up several inches.

This has caused problems for panel producers with appearance and wavy panels after installation. Manufacturers often try to raise the roll tooling to allow for the additional material thickness, which loses the effective over form needed to keep the panel within specifications.

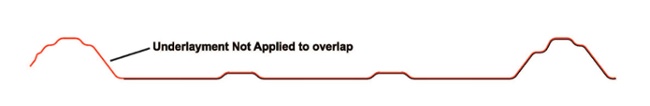

To add even more difficulty, the underlayment is typically not applied to the overlap. Unless the overlap form tooling is located on a dedicated pass, it becomes nearly impossible to adjust the rollformer to fix the cupping issue.

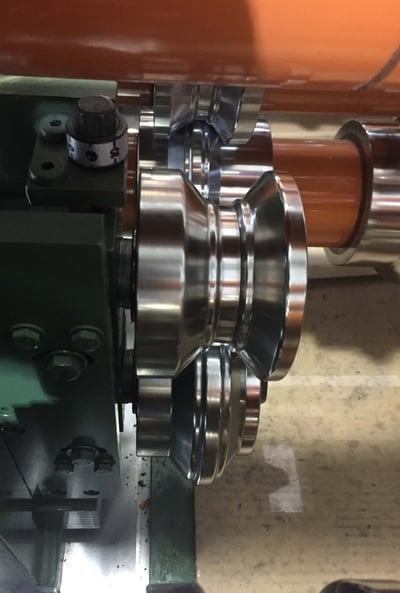

Side Roll fixture dedicated to the overlap rib

Side Roll fixture dedicated to the overlap rib

Bradbury has a vast amount of experience in designing roll tooling to run regular building panels and panels with underlayment applied that meet the same panel tolerances. This does involve additional passes to give independent control and side roll fixtures dedicated to the overlap rib. To speed the adjustment process between running felt and no felt panels, Bradbury can equip the line with single point adjustment on the stands. This allows the adjustments to be made from the operator side and keep the entire pass of tooling parallel.

Do you have questions or need assistance with your existing roll forming machine or are you looking for a new machine to give your company a competitive edge in your market? Contact us for a consultation.

Keep up to Date by subscribing to our updates.....you choose how often you get emails

1 min read

End flare can be inherent in roll formed parts, especially when produced on a precut roll forming line as opposed to a post cut line which forms the...

Are you considering purchasing your first roll former to produce metal building panels? Would you like some advice from a trusted expert? Ben...

With its wide range of advantages, Bradbury's AG roll tooling stands above its global competitors. Renowned for its ability to produce top-notch...