Bradbury Facilities Continue to Grow Rapidly

Over the past five years, Bradbury has continued to grow in Moundridge, Kansas. Our commitment to expanding and improving our facilities is evident...

3 min read

Jhet Burkhart

Aug 1, 2023 9:42:02 AM

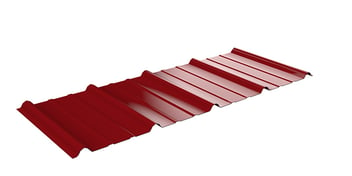

With its wide range of advantages, Bradbury's AG roll tooling stands above its global competitors. Renowned for its ability to produce top-notch panels and maintain exceptional production longevity, it has established itself as an industry leader. If you're seeking to manufacture consistently high-quality panels, our specially designed tooling is your solution. It not only prevents common deformities found in AG panels but also offers a longer lifespan in production.

Now, let's dive into the common deformities that can occur with AG panels, what causes them, and how Bradbury roll tooling can effectively prevent these issues. When trying to identify a tooling problem, it is important to closely examine the AG panels being produced. Signs such as wide panel coverage, reduced panel features, a wavy overlap edge, crossbow affecting panel flatness, large bending radii, and degraded cut quality on post-cut lines are all indicators that there may be an issue with the roll tooling. This could be due to regular wear and tear on the tooling or even from the use of a less reliable roll former.

To create a durable panel, tight bends are crucial, especially for roofing customers. If the panel appears wider than desired, it is likely that the major and minor ribs have lost their sharpness. Instead of creating sharp edges, the tooling causes the metal to spread out. This results in a round form on major ribs and a half-moon shape on minor ribs, rather than crisp, defined ribs. The panel appears wider because a round bend requires less steel. In the roofing industry, a weather-tight lap is essential. If a panel has a wavy edge, it cannot achieve a tight lap. The inconsistency in rib shapes makes it difficult for installers to overlap and secure the panels tightly.

Over time, as the tooling's bending radii wear and loosen, more pressure is needed to create a ¾” rib. Tightening the tooling causes the panel to lose its angles. Once the ability to adjust the panel is lost, maintaining flatness becomes challenging.

Fortunately, you may be able to resolve these issues by making adjustments to your machine. Calibrating your machine involves setting the vertical and horizontal clearances, as well as pass-to-pass settings to ensure alignment. If the calibration process does not result in satisfactory panel quality, you have three options: retrace or recut the roll tooling, replace partial tooling, or opt for a complete tooling replacement. However, it's important to note that putting new tooling on a worn-out machine will not solve the problem. For optimal improvement, it is recommended to replace the roll former stand bearings and adjustment assemblies. Additionally, inspecting sprockets, chains, spur gears, drive rolls, and arbors is advised.

Investing in quality equipment is a worthwhile decision. Here are a few advantages when choosing Bradbury AG roll tooling:

1. Bradbury AG panel tool sets come with a specialized bow correction fixture, eliminating the unsightly banana or canoe appearance of major ribs. Excessive bowing can lead to panels that don't lay flat and have open laps.

2. What sets Bradbury AG panel tool sets apart is their inclusion of 212 main forming rolls and 10 straightener rolls, which is approximately 40% more tooling pieces compared to other suppliers. This abundance of tooling allows for precise separation of critical over form bends, giving operators the flexibility to adjust for different steel types.

3. Bradbury AG panel tool sets require a minimum arbor diameter of 3.5 inches. This larger diameter reduces deflection, resulting in uniform formation of high wear features. The benefit of this uniformity is especially evident in the minor ribs of AG panels, where the tool set produces an identical middle cell to the outer minor ribs. In contrast, other suppliers often use smaller diameter arbors, which are more prone to deflection. This deflection affects the uniformity of the minor ribs, with the middle cells being noticeably less defined.

4. Designed with 7-inch pitch forming, Bradbury AG panel tool sets necessitate larger outside diameter rolls. These larger rolls provide more footage per revolution, giving the tool set better longevity.

5. Bradbury AG panel tool sets are constructed using through-hardened tool steel, allowing for recutting without compromising wear resistance. .jpg?width=354&height=207&name=Metal%20Roofing%20Image_2023_Metal%20of%20Honor%20(1).jpg)

Bradbury has been a respected leader in the metal building industry since 1959. Our machines produce top-quality products, giving our customers a competitive edge. Contact us today to learn how Bradbury equipment can enhance your production and increase your profits.

.jpg)

Over the past five years, Bradbury has continued to grow in Moundridge, Kansas. Our commitment to expanding and improving our facilities is evident...

.png)

Hayes International, located in Rotorua, New Zealand and part of The Bradbury Group, offers high-quality Panel roll formers that can be equipped with...

Do you want to produce tight tolerance metal building trim parts at a faster rate? The Bradbury 5X trim roll former offers several advantages for...