1 min read

FAQ: How is End Flare controlled in Roll Formed Profiles?

End flare can be inherent in roll formed parts, especially when produced on a precut roll forming line as opposed to a post cut line which forms the...

Are you considering purchasing your first roll former to produce metal building panels? Would you like some advice from a trusted expert? Ben Schmidt, Bradbury Industry Sales Manager for Metal Buildings, Trim & Decking, contributed an article for Rollforming Magazine covering basic information to help you determine if you are ready to start producing metal panels.

During his 17 years with Bradbury, Ben has been involved with over $260 million of Bradbury equipment installations. He has the knowledge and experience to guide you through the process and help determine the equipment that is right for you. Contact Ben if you have any questions or are considering purchasing a panel roll former.

+1.620.345.6394

1 min read

End flare can be inherent in roll formed parts, especially when produced on a precut roll forming line as opposed to a post cut line which forms the...

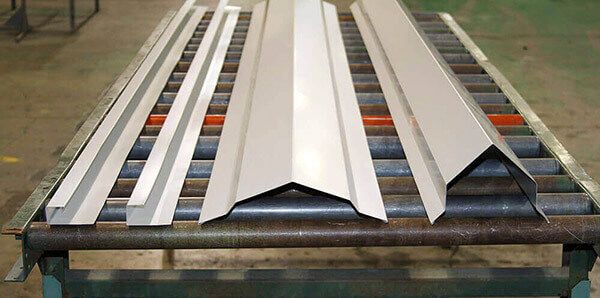

The Bradbury Co., Inc. has a new video featuring a Multi Profile Trim Roll Former. This machine produces the following four profiles: R-Panel Jamb...

1 min read

Metal Building panels with felt underlayment applied can look just as good as panels manufactured without. However, it does take some changes in the...