1 min read

Remembering Lloyd “Bob” Cring – A Legacy of Leadership and Craftsmanship

It is with heavy hearts that we share the passing of Lloyd (Bob) Cring, known to many as “Laser Bob.” Bob was more than a colleague, he was a mentor,...

.jpg?width=1800&height=900&name=Bob%20Laser%20(1).jpg)

1 min read

It is with heavy hearts that we share the passing of Lloyd (Bob) Cring, known to many as “Laser Bob.” Bob was more than a colleague, he was a mentor,...

1 min read

We are thrilled to introduce Heather Iddings as the newest member of our Technical Sales team at Alliance Machine & Engraving. Heather will be...

1 min read

The Alliance Machine and Engraving team is pleased to welcome Chris Merkel as the National Sales Manager. With over 15 years of experience in sales...

1 min read

Alliance Machine and Engraving, LLC, a member of The Bradbury Group, is proud to announce the release of a new and improved website!...

2 min read

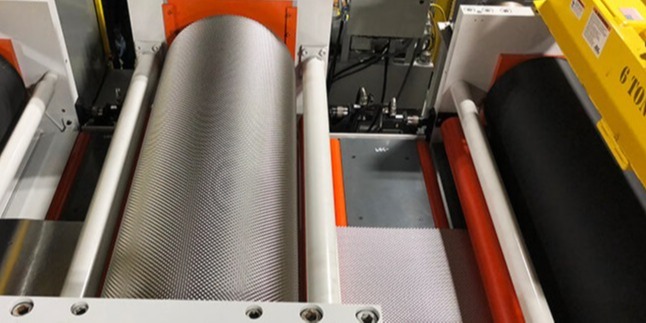

Calendering: A process that plays a part in all our lives, yet most of us have no idea what it is. From disposable diapers to dryer sheets, to...

1 min read

Alliance Machine and Engraving, a member of The Bradbury Group, announces a formal agreement with the Memco® division of Pamarco Global Graphics....

Receive notifications when we update the used equipment list!