1 min read

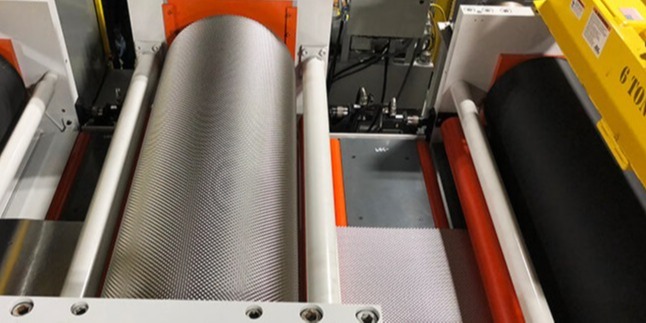

Introducing Heather Iddings, Embossing Sales & Applications at Alliance Machine & Engraving

We are thrilled to introduce Heather Iddings as the newest member of our Technical Sales team at Alliance Machine & Engraving. Heather will be responsible for sales in the composite, rigid plastic, and coated fabric markets.

Read More