1 min read

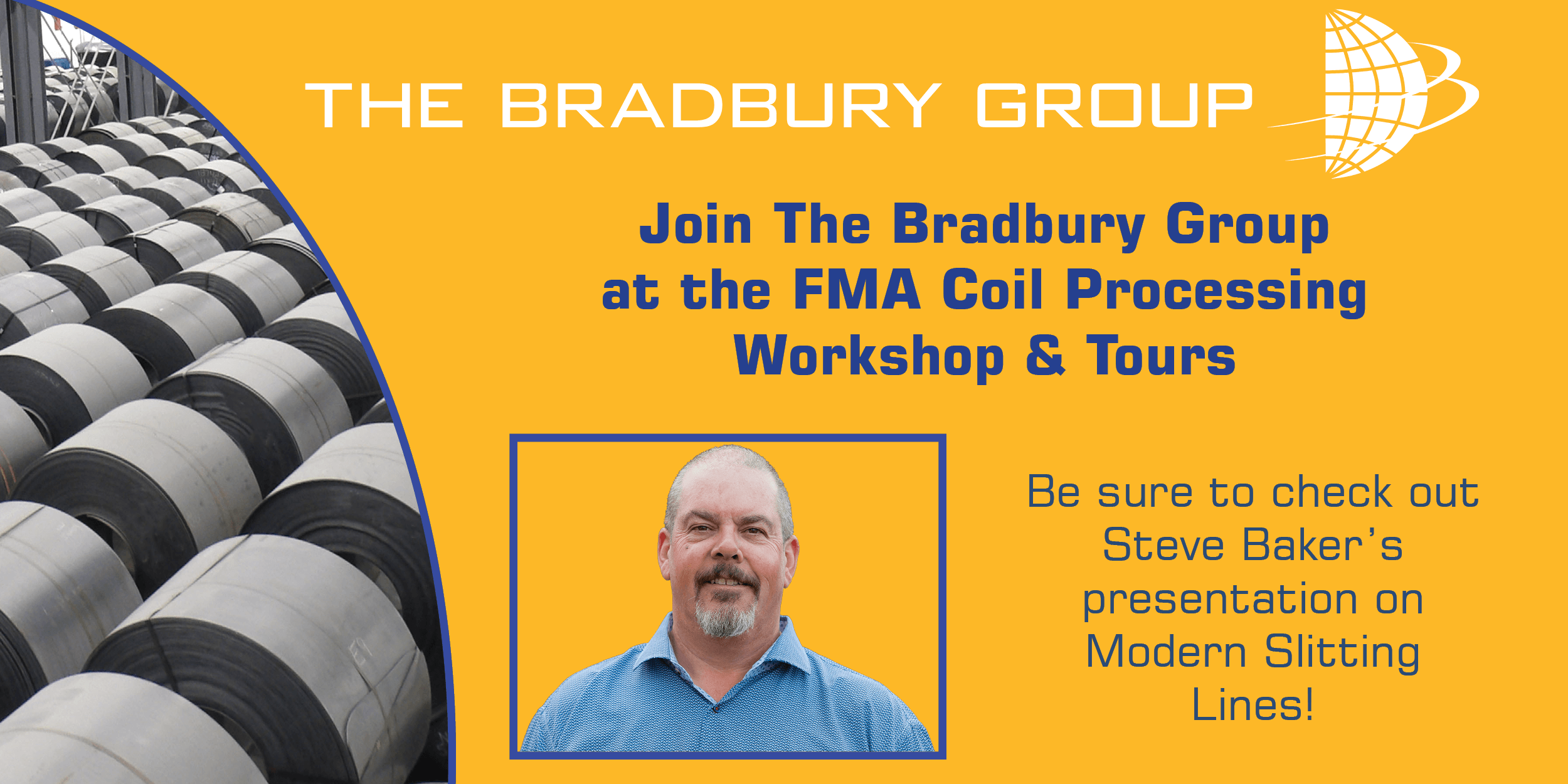

Steve Baker to Present on Modern Slitting Lines at Coil Processing Workshop

Steve Baker, Sales Area Manager for Athader S.L. and a member of The Bradbury Group, will be showcasing his expertise at the upcoming FMA Coil...

1 min read

Steve Baker, Sales Area Manager for Athader S.L. and a member of The Bradbury Group, will be showcasing his expertise at the upcoming FMA Coil...

1 min read

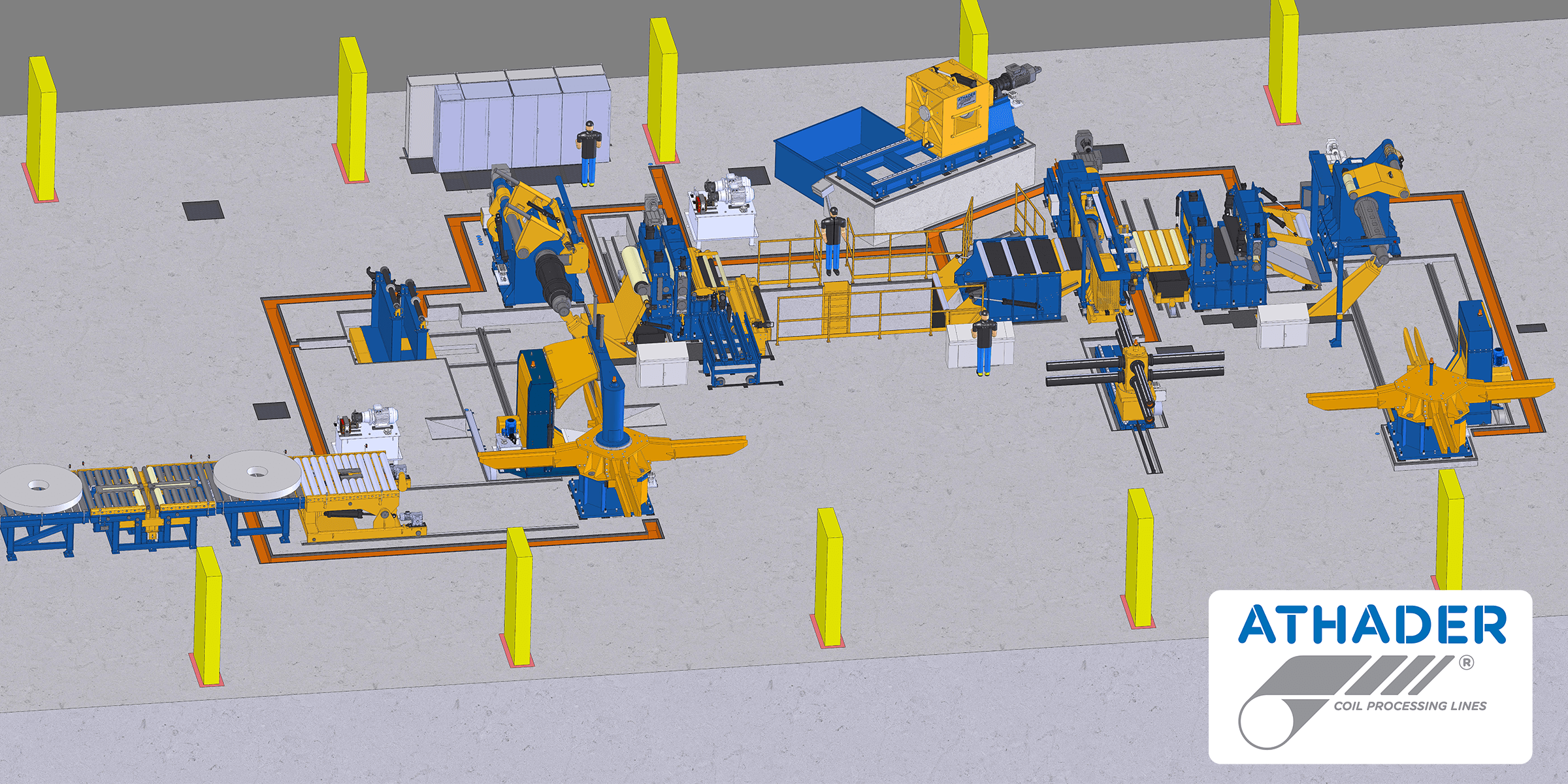

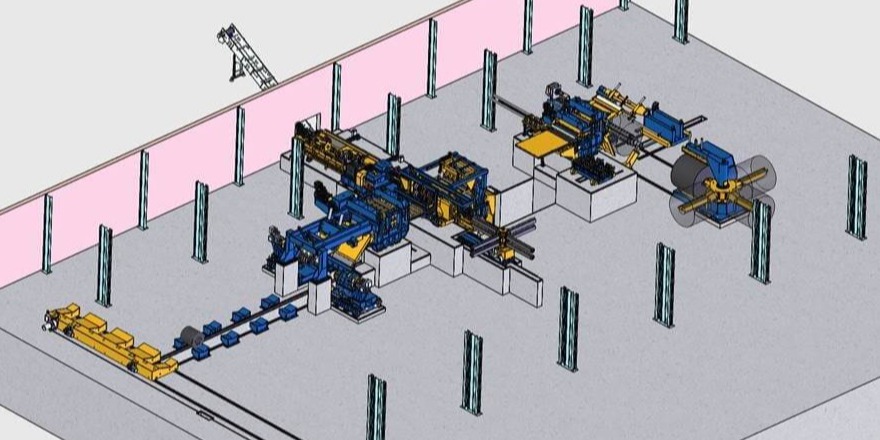

Venture Steel and Athader S.L. (The Bradbury Group) are pleased to announce Venture Steel has purchased a High Production Slitting Line from Athader....

1 min read

Steve Baker, a member of The Bradbury Group, will be showcasing his expertise at the FMA Coil Processing Workshop scheduled for April 2-3, 2024, in...

_tny.png?width=600&height=300&name=CR%20Slitters%20image_featured%20image%20(2)_tny.png)

1 min read

CR Slitters and Athader S.L. (The Bradbury Group) are pleased to announce CR Slitters purchase of a High Production Slitting Line from Athader. The...

%20sm.jpg?width=800&height=400&name=Image%20for%20blog%20(2)%20sm.jpg)

1 min read

Modern Metals published an article in their August 2022 issue highlighting Bailey Metal Products' decision to purchase an Athader slitting line and...

1 min read

Steve Baker with The Bradbury Group will present at the FMA Coil Processing Workshop on September 20 - 21, 2022, in Corpus Christi, TX. Steve joined...

2 min read

Written by Steve Baker, Athader Sales Area Manager Nova Steel Inc. and The Bradbury Co., Inc. announce Nova Steel's purchase of two Thrive e-Drive³...

1 min read

The Bradbury Group announces the addition of Thomas Hofstetter to its North American customer service and sales support team. As a Service Technician...

1 min read

Nova Steel Inc. recently purchased a Heavy Gauge Slitting Line from Athader S.L., a member of The Bradbury Group. The line, to be installed in the...

1 min read

Steve Baker, Sales Area Manager for Athader S.L., will present "Advanced Features of Modern Coil Processing Lines" at the FMA (Fabricators &...

Receive notifications when we update the used equipment list!