Automating the Future: Beck Automation Custom Robotic Folder Solution

Manufacturing facilities continue to look for ways to streamline production, improve efficiency, and make the most of their workforce. Beck...

2 min read

Jhet Burkhart

Mar 21, 2024 9:50:24 AM

In the fast-paced world of manufacturing, efficiency and seamless operation are paramount. Norwalk Innovation, a leader in industrial equipment, introduces a game-changer with their high-efficiency flat stock uncoiling systems. Designed under the brand name Un-Coilers by Press Room Equipment, these systems are meticulously crafted to enhance productivity while ensuring ease of operation. Let's take a look at what makes these systems a must-have for modern production facilities.

Streamlined Operation for Seamless Production Flow

One of the standout features of Norwalk Innovation's Un-Coilers is their ability to facilitate coil changes with minimal disruption to the production flow. Operators can swiftly load the Un-Coiler, and thanks to its intuitive design, guiding the first coil around the drum and into the production machine's feed mechanism takes a mere five minutes. This streamlined process translates to significant time savings and optimized production schedules.

Quick Torque Drive System for Precision Control

At the heart of the Un-Coiler's exceptional performance is its Quick Torque drive system. This innovative technology ensures responsive starting and stopping, eliminating excess coasting and ensuring precise control over the feeding action. Whether uncoiling a full load or nearing empty, the tension remains constant, guaranteeing consistent and high-quality output.

Impressive Specifications for Varied Applications

Norwalk Innovation offers a range of Un-Coilers to suit different production needs. Here's a glimpse of their specifications:

User-Friendly Design and Robust Construction

In addition to their impressive technical specifications, Norwalk Innovation's Pallet Un-Coilers boast a user-friendly design that enhances operator convenience. The systems are built to last, with robust construction that ensures durability even in demanding industrial environments. Moreover, with options for different power configurations, these Un-Coilers seamlessly integrate into existing production setups.

Stock Lead Time for Seamless Planning

Norwalk Innovation understands the importance of timely delivery in manufacturing operations. The stock lead time for Un-Coilers is carefully managed to ensure that customers can plan their production schedules with confidence. This proactive approach to inventory management adds another layer of efficiency to the overall production process, allowing businesses to meet deadlines and maintain seamless operations. Contact us today to learn more about our stock availability and lead times.

Norwalk Innovation's High-Efficiency Flat Stock Uncoiling Systems represent a significant advancement in the realm of industrial equipment. Their ability to enhance production efficiency, coupled with ease of operation and robust construction, makes them indispensable for modern manufacturing facilities. Whether handling light or heavy-duty applications, these Un-Coilers deliver consistent performance and contribute to streamlining production processes. Embrace the future of manufacturing with Norwalk Innovation's innovative Un-Coilers by Press Room Equipment.

WE BUILD MACHINES. WE SELL SOLUTIONS.

+1.417.864.3636.

.jpg)

Manufacturing facilities continue to look for ways to streamline production, improve efficiency, and make the most of their workforce. Beck...

When Randall Metals Corporation needed a new high-speed production slitting line, they knew they wanted the most technologically advanced, safe, and...

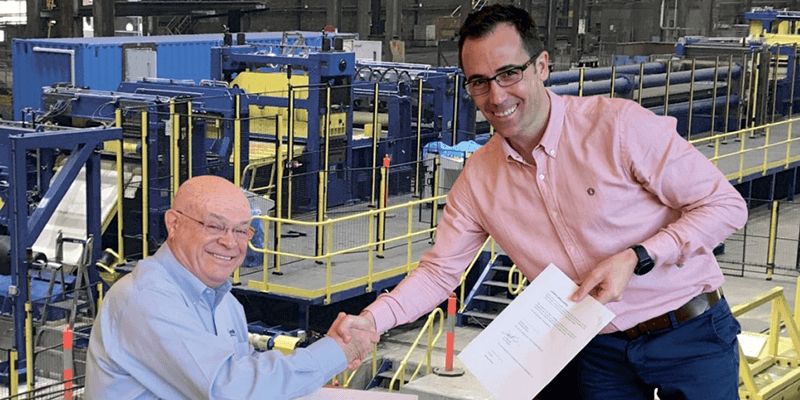

Athader and Leveltek Sign a Strategic Agreement for Stretch Leveler Cut-To-Length Lines Athader, A Bradbury Group Company located in Spain, has...