A Bradbury BOSS Shear Rebuild Now Available in Your Facility!

Bradbury's BOSS™ shear is a vital part of your production process and we can assist in ensuring it runs at its top performance level by completing a...

1 min read

Rachel Grilliot Mar 9, 2022 8:45:00 AM

CONTACT BRADBURY TO DISCUSS YOUR SPARE PARTS INVENTORY PLANNING!

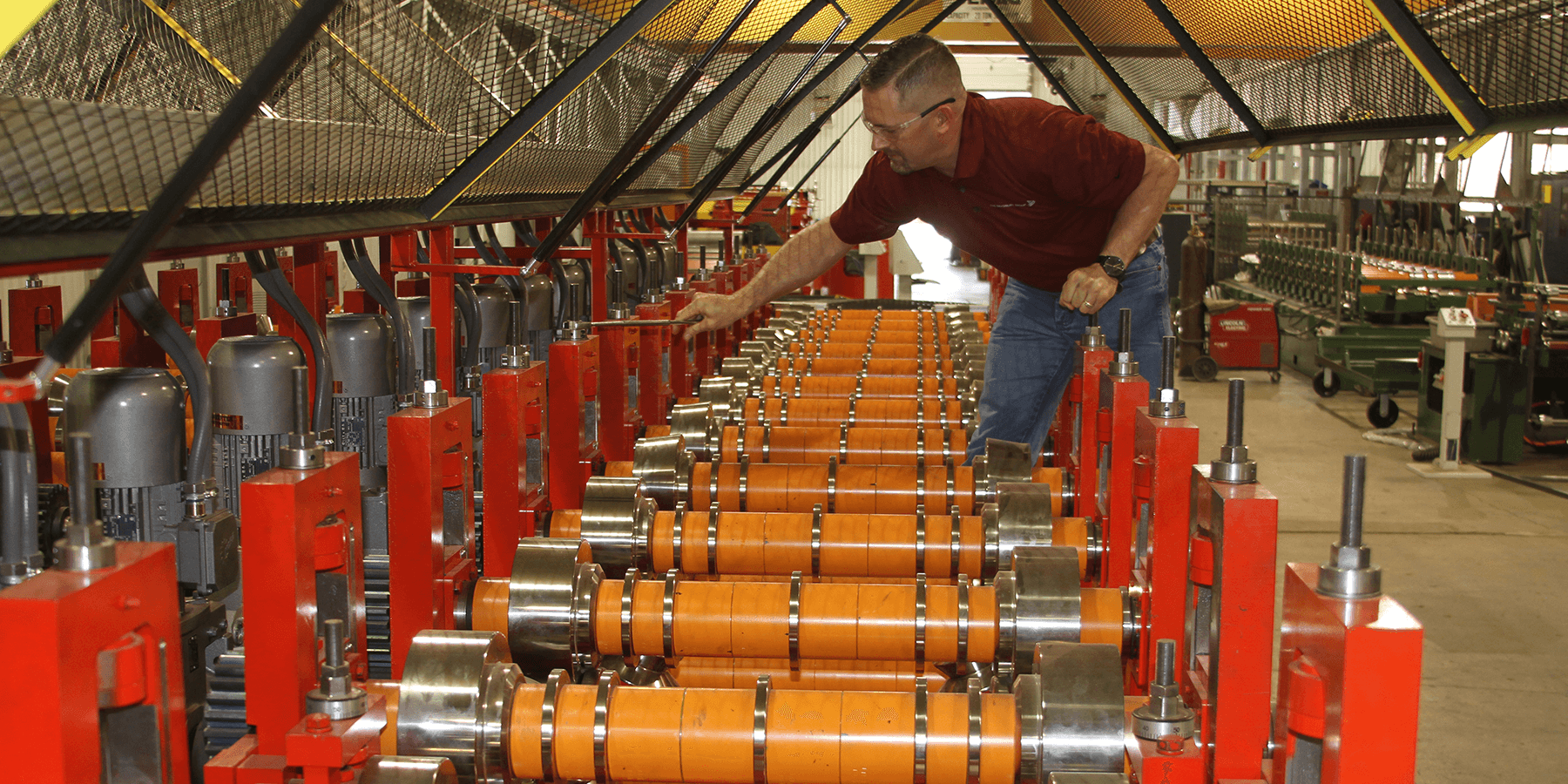

The world is experiencing a global supply chain crisis we have not encountered at Bradbury in our 62 years of business. Due to the supply chain crisis, we face price increases and extended lead times for numerous parts. Although we work closely with our vendors to negotiate prices and manage our inventory logistics, the uncontrollable supply chain adversity could impact your business and production schedules should you need replacement parts. As your industry partner, we advise you to contact us to discuss your spare parts inventory planning.

work closely with our vendors to negotiate prices and manage our inventory logistics, the uncontrollable supply chain adversity could impact your business and production schedules should you need replacement parts. As your industry partner, we advise you to contact us to discuss your spare parts inventory planning.

Potentially, all needed items could have extended lead times, but currently, electrical components and hydraulic motors are the most difficult items to get quickly.

For example, electrical components ordered today could have a 30+ week delivery date. If a distributor does not have a hydraulic motor on the shelf, delivery time could be out 40 weeks.

Our customer service team will consult with you regarding a proactive plan to optimize your spare parts inventory. Having crucial spare parts on the shelf when you need them will get you back into production quickly. We encourage you to be prepared and order before you need a replacement part, not when you need it. A single missing equipment part can quickly affect production processes negatively.

Bradbury is committed to providing you with world-class customer service through our Technical Service Departments. Our staff is ready to assist you with your spare parts needs, service contracts, technical questions, and training.

WE BUILD MACHINES. WE SELL SOLUTIONS.

Bradbury's BOSS™ shear is a vital part of your production process and we can assist in ensuring it runs at its top performance level by completing a...

Maintenance is essential for the efficient operation of any machine, and roll formers are no exception. At Bradbury, we offer a range of...

Marion Die & Fixture offers complete maintenance programs for dies. From evaluation and reset to complete component and tooling replacement, MDF will...