1 min read

Bradbury Discontinuous Insulated Metal Panel Line For Sale

At The Bradbury Group we currently have a discontinuous insulated metal panel line in stock and ready for immediate shipment. This highly versatile...

1 min read

At The Bradbury Group we currently have a discontinuous insulated metal panel line in stock and ready for immediate shipment. This highly versatile...

1 min read

Bradbury Group is a member of the MCA's IMP Alliance. Check out our spotlight feature on the Metal Construction Association Website. As a member of...

1 min read

The Bradbury Double Belt Provides Finished Sandwich Panels without Blemish Bradbury supplies complete, continuous, foam-filled panel production lines...

1 min read

The Bradbury Coil Joining Unit Keeps Your IMP Production Running A continuous sandwich panel line needs to run production non-stop even during a coil...

1 min read

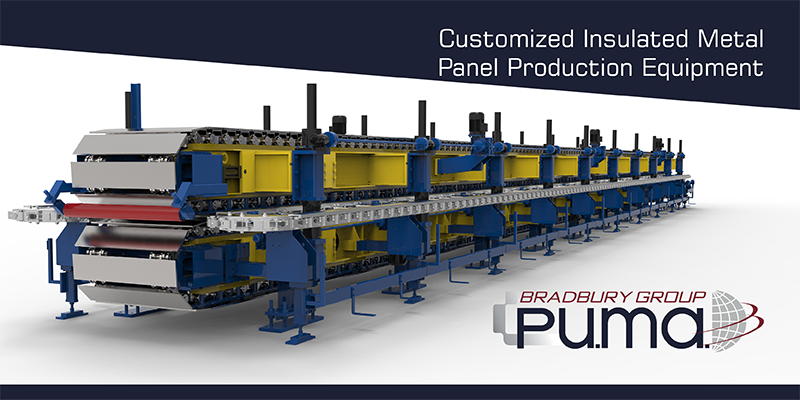

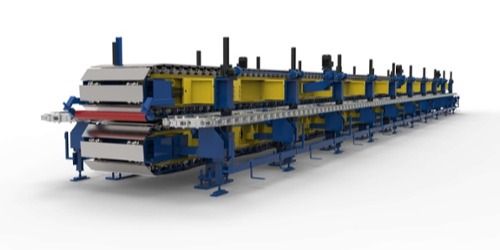

To best serve the growing Insulated Metal Panel Industry, The Bradbury Group offers complete Insulated Metal Panel production lines. The Bradbury...

1 min read

The Bradbury Co., Inc. received a testimonial from a valued customer, Climate Craft, Inc. "Bradbury engineered our system as a versatile, dual-mode...

Bradbury Group Australia, working with Bradbury Group Pu.ma., has designed an entry level, low-cost solution for PU insulated panel manufacturing....

Bradbury Group Pu.Ma. is a leading Italian manufacturer making the Bradbury Pu.Ma. brand of equipment which produces PUR/PIR insulated sandwich...

1 min read

The Bradbury Co., Inc. received a new testimonial from Green Span Profiles Insulated Panel Technologies. Kelly Ginn stated, "Embossing is a critical...

Receive notifications when we update the used equipment list!