Is it time for you to invest in a Panel rollformer?

Are you considering purchasing your first roll former to produce metal building panels? Would you like some advice from a trusted expert? Ben...

Cutting gable ends in the field can be time consuming, increase the risk of damage and creates unnecessary waste.

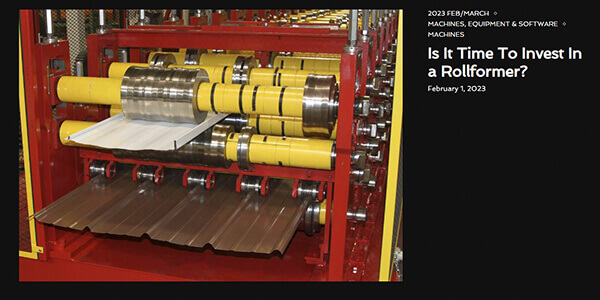

The following video shows our Hayes International Post Cut metal panel roll forming machine with an integrated miter shear. This line was configured as a post cut with the ability to produce short straight and mitered cut sheets. The operator is able to enter their cut list into the Beck SII control, or download the list from the office, then run the building pack w

ith gable ends being processed inline. When a miter is cut, opposite comers of the building are produced. With the stacking system, each corner of the building is stacked separately, eliminating the need to sort panels on the job site. With a 4 on 12 pitch, 1 linear foot of steel is saved per miter cut.

These post cut shears can be designed for pitch specific cuts to produce a good quality cut. This pivoting shear is rafted, so when running other pitches, it is easily removed, and a different pitch shear is mounted.

Integrating gable cutting into your roll forming operation can save steel, installation time in the field and require less material handling.

To see more panel roll former videos please visit, http://info.bradburygroup.com/panel-lines-video-playlist

Are you considering purchasing your first roll former to produce metal building panels? Would you like some advice from a trusted expert? Ben...

At The Bradbury Group we currently have a used canopy panel roll former, ready for immediate delivery. This machine is located at our headquarters...

Do you need additional manufacturing capacity? Do you need equipment delivered before year end for tax savings? Bradbury has the following pieces...