Product Spotlight: Bradbury Light Structural Viper Line

The Bradbury Light Structural Steel Framing line is designed to produce 14 ga. - 20 ga. stud and track products at speeds up to 500 FPM. The typical...

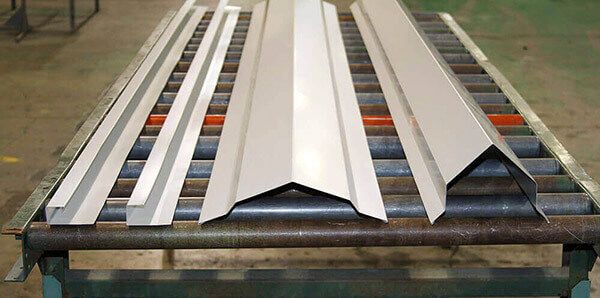

The Bradbury Group offers multiple options when it comes to Metal Roofing and Siding roll formers. This product spotlight features a Hayes Single Level Panel roll former, Bradbury Flying Post Cut Shear, and Beck Automation closed loop controls. This line is also designed to run moisture barrier underlayment and produce quality panels with or without felt.

The Beck Automation Smart Cut feature tracks the last piece of a batch automatically through the line. This allows the operator to finish the order in automatic mode with the correct amount of steel in the roll former. The double end uncoiler can be rotated so a new coil can be threaded.

The roll tooling is designed to be able to run with or without underlayment. This requires additional passes and specifically designed overform capabilities for consistent production.

The flying post cut shear can produce panels at 200 FPM through put with an up cut shear to avoid scratching when running out panels on a stack. As seen in the video, the line is not limited with a minimum panel length nor does the machine limit the maximum length that can be produced. The closed loop Beck SII controller is a touch screen, networkable with multiple production management systems for download/upload and achieves a length tolerance of +/- 1/16".

For more information on Bradbury Roll Formers, visit http://bradburygroup.com/Products/Metal-Building-and-Roofing-Manufacturing-Equipment/Panel-Rollforming-Lines

Do you need to up your production or produce a panel that beats your competition? Give us a call at +1.620.345.6394 or click the button below.

The Bradbury Light Structural Steel Framing line is designed to produce 14 ga. - 20 ga. stud and track products at speeds up to 500 FPM. The typical...

The Bradbury Co., Inc. has a new video featuring a Multi Profile Trim Roll Former. This machine produces the following four profiles: R-Panel Jamb...

The Bradbury Co., Inc. has a new video featuring a Flying Patriot Shear. This machine can be retrofitted into an existing line or purchased with a...