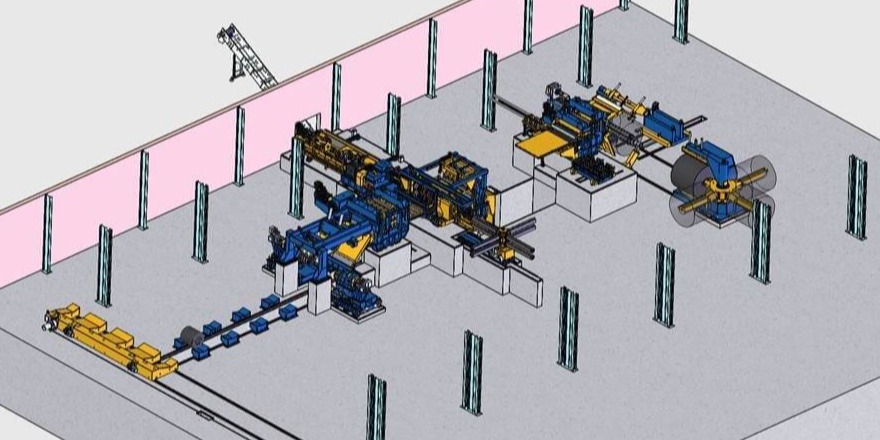

Nova Steel purchases Athader Heavy Gauge Slitting Line

Nova Steel Inc. recently purchased a Heavy Gauge Slitting Line from Athader S.L., a member of The Bradbury Group. The line, to be installed in the...

1 min read

Rachel Grilliot May 27, 2020 9:00:00 AM

Most Cut to Length lines suffer from a bottleneck in production at the exit end of the line due to customers' unique  requirements for packaging the CTL sheets or plates. These customer-driven stipulations can be quite extensive and labor-intensive for the line operators. End customers today are requesting smaller stacks and more frequent deliveries to manage their cash flow more effectively. This puts additional pressure on the line operator due to the increased number of packaged stacks the line must produce.

requirements for packaging the CTL sheets or plates. These customer-driven stipulations can be quite extensive and labor-intensive for the line operators. End customers today are requesting smaller stacks and more frequent deliveries to manage their cash flow more effectively. This puts additional pressure on the line operator due to the increased number of packaged stacks the line must produce.

Requirements from the end customer might include the following:

Athader S.L., a company within The Bradbury Group, offers the following automated stacking and packaging solutions to improve throughput efficiency:

The automated packaging of sheets or plates can be custom engineered to suit the line operation requirements. Using these automated features, lines have increased output up to 30%, allowing the owner to reduce manpower and increase productivity.

The automated packaging of sheets or plates can be custom engineered to suit the line operation requirements. Using these automated features, lines have increased output up to 30%, allowing the owner to reduce manpower and increase productivity.

Athader S.L. designs and manufactures Slitting, CTL, and Packaging lines for both Slit Coils and CTL Sheets/Plates. Learn more about our products at www.athader.com.

Call +1.620.345.6394

Nova Steel Inc. recently purchased a Heavy Gauge Slitting Line from Athader S.L., a member of The Bradbury Group. The line, to be installed in the...

When Randall Metals Corporation needed a new high-speed production slitting line, they knew they wanted the most technologically advanced, safe, and...

_tny.png)

CR Slitters and Athader S.L. (The Bradbury Group) are pleased to announce CR Slitters purchase of a High Production Slitting Line from Athader. The...