Learn About Advanced Features of Coil Processing Lines at the FMA Workshop

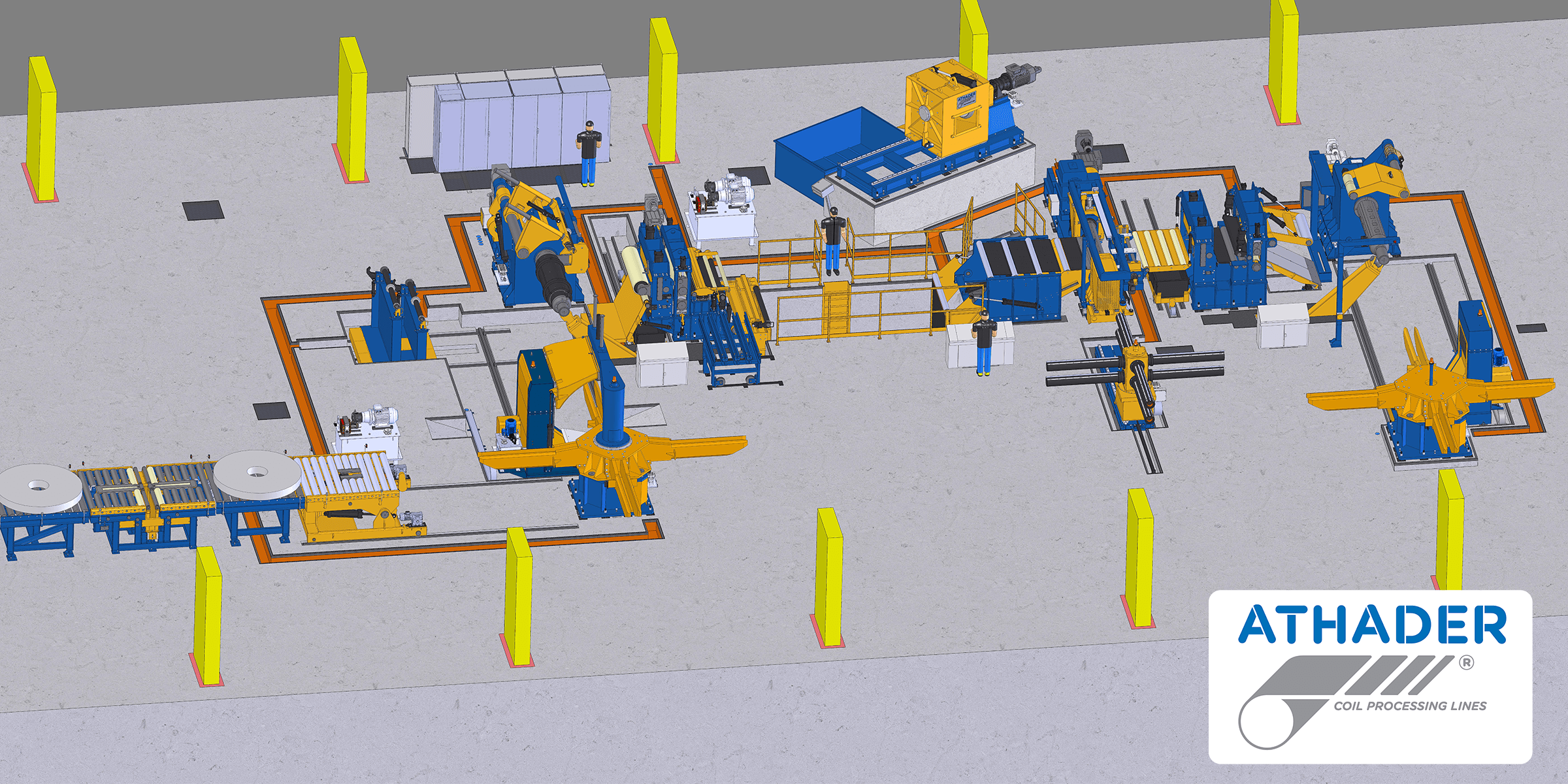

Steve Baker, Sales Area Manager for Athader S.L., will present "Advanced Features of Modern Coil Processing Lines" at the FMA (Fabricators &...

3 min read

Rachel Grilliot Jul 21, 2020 2:44:51 PM

Bradbury AG Roll Tooling is Designed to Form the Best Panels in the Industry

By Ben Schmidt, Bradbury Industry Sales Manager

Did you know Bradbury AG roll tooling offers several advantages our competitors do not? From forming a superior panel to production longevity, Bradbury AG roll tooling leads the industry. If you want to manufacture consistent, top-quality panels, our tooling is designed to prevent common AG panel deformations and have a longer production life.

production longevity, Bradbury AG roll tooling leads the industry. If you want to manufacture consistent, top-quality panels, our tooling is designed to prevent common AG panel deformations and have a longer production life.

Let’s take a brief look at common AG panel deformities, what causes them, and why Bradbury roll tooling can help prevent these issues. Typically, to diagnose a tooling issue, one should assess the AG panel that is being produced. Panel coverage running wide, reduced panel features, wavy overlap edge, crossbow (panel flatness), large bending radii, and degraded cut quality on post-cut lines are signs there is likely a problem with the roll tooling. It could be caused by normal wear and tear with the tooling, or it might be a low-quality roll former and tooling.

Creating a panel with tight bends is the key to a stronger panel – which is crucial to the roofing customer. If the panel is running wide, most likely the major and minor ribs have a reduction in sharpness. The tooling is causing the metal to spread out instead of creating sharp edges. On the major ribs, the form will start to round. On minor ribs, it may turn into a half-moon instead of a crisp rib. The panel is wider because a round bend does not take as much steel.

As the bending radii of the tooling start to wear and loosen over time, it takes more pressure to create a ¾” rib. As the tooling comes down tighter it causes the panel to lose angles; once the ability to adjust the panel is lost, the ability to control flatness is lost.

In the roofing business, a weather-tight lap is essential. If a panel has a wavy edge it will not have a tight lap. It’s challenging for installers to get a tight lap if the ribs are not consistent in the panels being installed and overlapped.

You may be able to find a solution to these common issues with a few adjustments to your machine. By calibrating your  machine, you will set your vertical clearances, your horizontal clearances, and your pass-to-pass settings to confirm alignment. Bradbury offers a roll tooling training course which includes classroom instruction and hands-on training led by Ron Dies, Bradbury Technical Training Director & Preventative Maintenance.

machine, you will set your vertical clearances, your horizontal clearances, and your pass-to-pass settings to confirm alignment. Bradbury offers a roll tooling training course which includes classroom instruction and hands-on training led by Ron Dies, Bradbury Technical Training Director & Preventative Maintenance.

If you still have sub-par quality panels after the calibration process, you have three options: retrace or recut the roll tooling, partial tooling replacement, or a complete tooling replacement. However, putting new tooling on a worn-out machine will not solve your problem. For optimal improvement, you will need to replace the roll former stand bearings and the adjustment assemblies. We also recommend inspecting sprockets, chains, spur gears, drive rolls, and arbors.

Quality equipment is well worth the investment. Here are a few advantages of investing in Bradbury AG roll tooling:

All Bradbury AG panel tool sets come with a bow correction fixture. The bow correction fixture removes the banana or canoe appearance of major ribs. Bow occurs because a small bend is formed in a small area. Excessive bow can result in an open lap and a panel that does not lay flat.

Bradbury AG panel tool sets have 212 main forming rolls and 10 straightener rolls. On average, this is 40% more pieces of tooling than other suppliers. More pieces of tooling allow critical overform bends to be separated. Separating overform bends provides an operator with the opportunity to adjust for different types of steel.

Bradbury AG panel tool sets require a minimum of 3.5” diameter arbors. Larger arbor diameter reduces the amount of deflection. Reducing deflection provides uniform forming of high wear features. Specific AG panel high wear features are the minor ribs. Bradbury AG panel tool set produces an identical middle cell of minor ribs to the outer minor ribs. Other suppliers use a 3” (or smaller) diameter arbor which has a higher likelihood of arbor deflection. Arbor deflection is exposed in high wear areas on AG panels. Tool sets with arbor deflection do not produce a uniform minor rib. The middle cells are significantly less defined than the other cells.

Bradbury AG panel tool sets require a minimum of 3.5” diameter arbors. Larger arbor diameter reduces the amount of deflection. Reducing deflection provides uniform forming of high wear features. Specific AG panel high wear features are the minor ribs. Bradbury AG panel tool set produces an identical middle cell of minor ribs to the outer minor ribs. Other suppliers use a 3” (or smaller) diameter arbor which has a higher likelihood of arbor deflection. Arbor deflection is exposed in high wear areas on AG panels. Tool sets with arbor deflection do not produce a uniform minor rib. The middle cells are significantly less defined than the other cells.

Bradbury AG panel tool sets are designed with 7” pitch forming. The larger equal geared pitch forming requires larger outside diameter rolls. The larger rolls result in more footage per revolution which creates better longevity for a tool set.

Bradbury AG panel tool sets are made with through-hardened tool steel. Through hardened tool steel allows tool sets to be recut and still provide the same level of wear resistance. Other suppliers achieve wear resistance by applying a thick level of chrome to unhardened tools. When the chrome wears off, the unhardened tools will be damaged to the point of not being able to recut, which results in purchasing new tools. Thick layers of chrome can create buildup which can change the engineered tooling clearances.

Since 1959, Bradbury has been a respected leader in the metal building industry. The products being formed on our machines are top quality and bring a competitive edge to our customers. Call to discuss how Bradbury equipment can increase your production and profit.

Call +1.620.345.6394

Steve Baker, Sales Area Manager for Athader S.L., will present "Advanced Features of Modern Coil Processing Lines" at the FMA (Fabricators &...

Venture Steel and Athader S.L. (The Bradbury Group) are pleased to announce Venture Steel has purchased a High Production Slitting Line from Athader....

.png)

At Bradbury, our top priority is helping customers maintain long-term operational stability. As equipment ages, older control systems, such as legacy...